ICM-42607-P | 6-axis MEMS IMU sensor

- Part No.:

- ICM-42607-P

- Manufacturer:

- TDK InvenSense

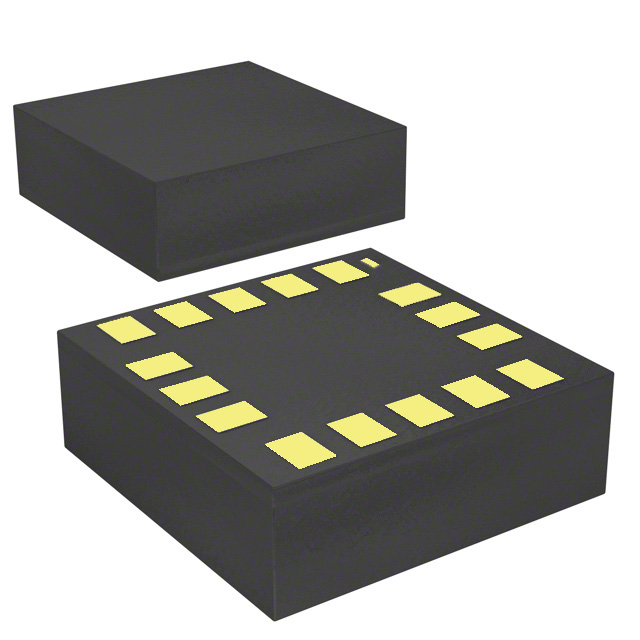

- Package:

- LGA-14(2.5x3)

- Description:

- MOTION SENSOR

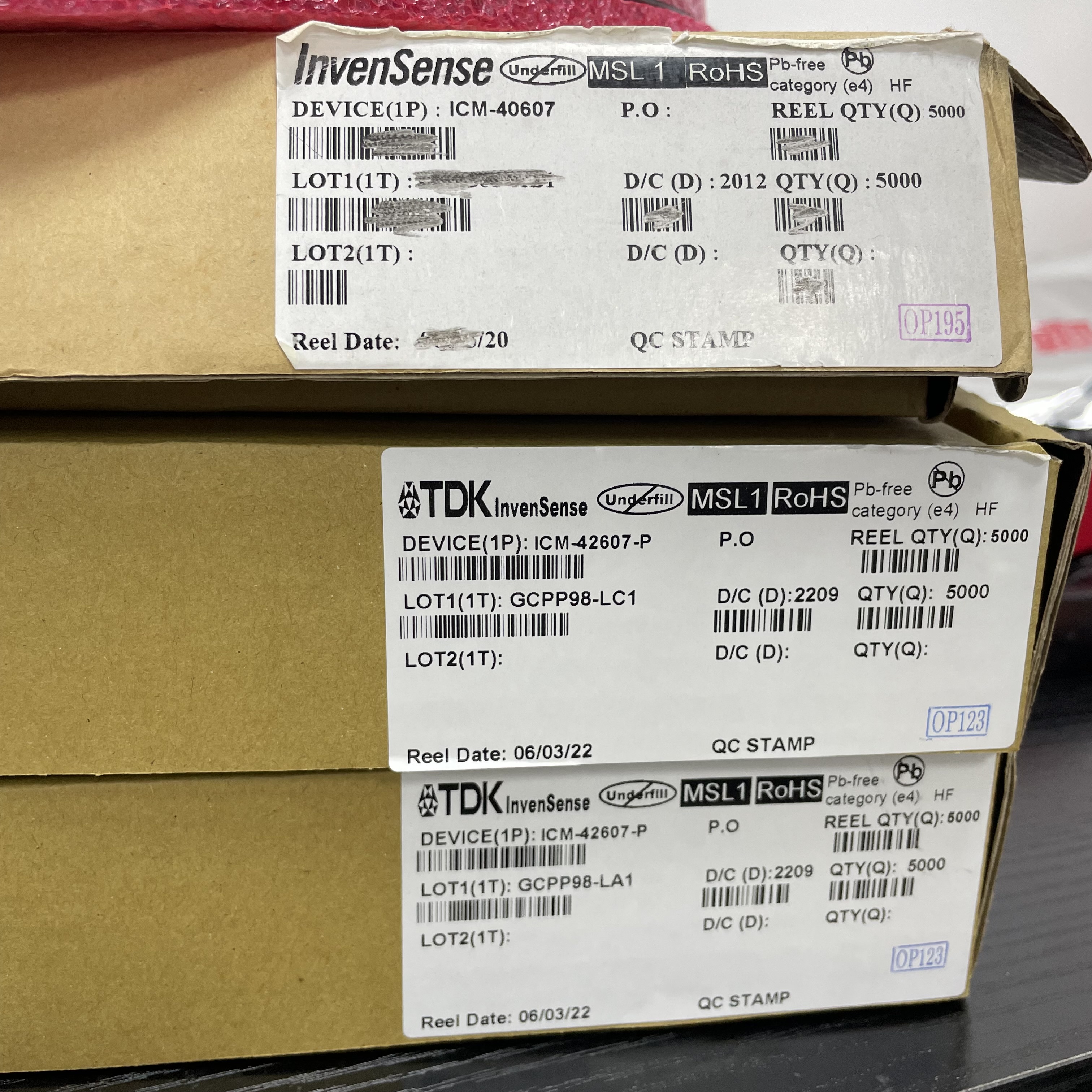

- Quantity:

- Payment:

- Shipping:

Article Details

- Details

- Specifications

- Comparison

The ICM-42607-P is a high-performance 6-axis inertial measurement unit (IMU) sensor that integrates a 3-axis gyroscope and a 3-axis accelerometer. It is commonly used in scenarios requiring precise motion sensing and attitude tracking.

Get to Know ICM-42607-P

Highlights

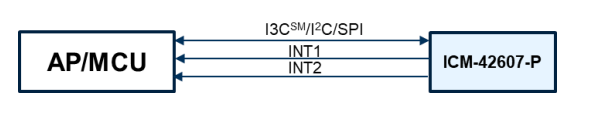

- Configurable host interface supporting I3CSM, I2C and SPI serial communication

- Up to 2.25 KB FIFO and 2 programmable interrupts

- Supports ultra-low power motion wake-up to minimize system power consumption

- Supports the lowest gyroscope and accelerometer noise among such IMUs

- Features the highest stability against temperature, shock (up to 20,000g) or SMT/bending-induced offsets, as well as immunity to out-of-band vibration-induced noise

- Supports a VDD operating range of 1.71V to 3.6V

- Supports a separate VDDIO operating range of 1.71V to 3.6V

Features

- Gyroscope Noise: 7 mdps / Hz &Accelerometer Noise: 100 µg/Hz

- Low-Noise mode 6-axis current consumption of 0.55 mA

- Low-Power mode support for always-on experience

- User selectable Gyro Full-scale range (dps):± 250/500/1000/2000

- User selectable Accelerometer Full-scale range (g): ± 2/4/8/16

- User-programmable digital filters for gyro, accel , and temp sensor

- APEX Motion Functions: Pedometer, Tilt Detection, Low-g Detection, Freefall Detection, Wake on Motion, Significant Motion Detection

- Host interface: 12.5 MHz I3CSM, 1 MHz I2C,24 MHz SPI

Physical and Electrical Specifications

- Package Dimensions: 2.5 × 3 mm, 14-pin LGA small package, suitable for integration in space-constrained devices.

- Operating Voltage: 1.71 V ~ 3.6 V (VDD and VDDIO)

- Operating Temperature: −40 °C ~ +85 °C (typical industrial range).

- Output Resolution: 16-bit data output.

- Impact Resistance: Up to 20,000 g, enhancing mechanical reliability.

Applications

- Smartphones, Computers, Tablets

- Smart Watches and Fitness Trackers

- Augmented & Virtual Reality Headsets andControllers

- Game Controllers

- Drones and Robotics

Use ICM-42607-P

How does ICM-42607-P work?

1. The main modules and internal structure of the ICM-42607-P sensor:

- Three-axis MEMS gyroscope

- Three-axis MEMS accelerometer

- I3CSM, I2C, and SPI serial communications interfaces to Host

- Self-Test

- Sensor Data Registers

- FIFO

- Interrupts

- Digital-Output Temperature Sensor

- Bias and LDOs

- Charge Pump

- Standard Power Modes

- Utilizing the Coriolis effect

- Mechanical displacement of the vibrating structure is detected by capacitance

- The signal is amplified, demodulated, filtered, and ultimately converted into digital values

The ICM-42607-P includes a 3-axis MEMS accelerometer. Acceleration along a specific axis causes the displacement of the detection mass in the MEMS structure, and the capacitive sensor detects this displacement. The ICM-42607-P architecture reduces the sensitivity of the accelerometer to manufacturing variations and thermal drift. When the device is placed on a flat surface, the measured values on the X and Y axes are 0g, and the measured value on the Z axis is +1g. The ratio factor of the accelerometer is calibrated in the factory and is nominally independent of the power supply voltage. The full-scale range of the digital output can be adjusted to ±2g, ±4g, ±8g, and ±16g.

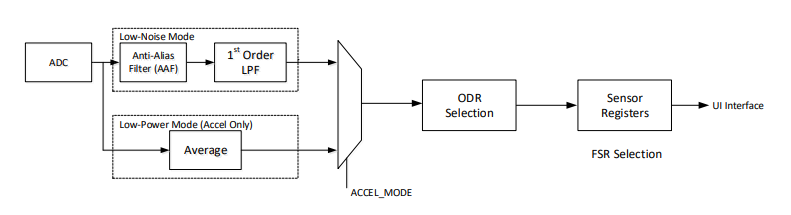

4. Signal processing mechanism

Key points of the ICM-42607-P signal path:

- The signal starts from the ADC of the gyroscope/accelerometer.

- Accelerometer: Supports low noise mode and low power consumption mode.

- Gyroscope: Only supports low noise mode.

- Low noise mode:

- ADC → Unconfigurable AAF → Configurable first-order LPF

- Low power consumption mode (only for the accelerometer):

- ADC → Configurable average filter

- After filtering, the ODR (Output Data Rate) is selected

- Finally, the FSR (Full Scale Range) is selected to determine the output range

QFA

Q1: What is the working principle of the accelerometer?The acceleration along a specific axis causes the MEMS to detect a change in mass position, and the capacitive sensor detects this displacement and converts it into a digital signal.

Q2: Which working modes are supported?

Accelerometer: Supports low-noise mode and low-power mode

Gyroscope: Only supports low-noise mode

Q3: Has the factory calibration been performed?

Yes, the scale factor of the accelerometer has been calibrated in the factory and is nominally independent of the power supply voltage.

- Product attributes

- Attribute value

- Manufacturer:

- TDK InvenSense

- Series:

- -

- Package/Case:

- LGA-14(2.5x3)

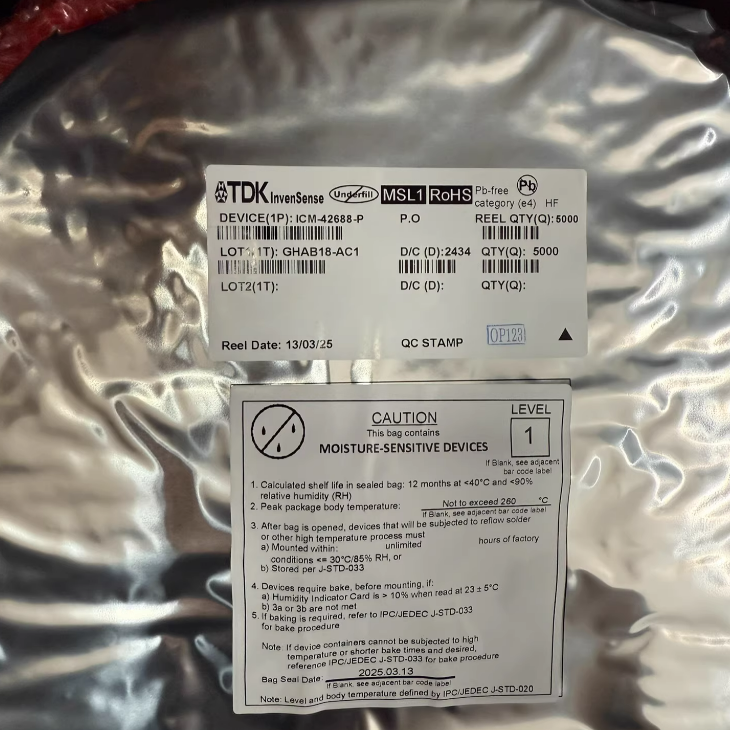

- Packaging:

- Tape & Reel (TR)

- Part Status:

- Active

- Resistance:

- Accelerometer, Gyroscope, 6 Axis

- Tolerance:

- -

- Composition:

- -

- Features:

- -

- Temperature Coefficient:

- -

- Operating Temperature:

- -

- Supplier Device Package:

- Power (Watts):

- -

- Ratings:

- Size / Dimension:

- Height - Seated (Max):

- Number of Terminations:

- Failure Rate:

| Image |  |

|

|

|

|

| Part Number | ICM-42670-P | ICM-42605 | ICM-20602 | ICM-42688-P | ICM-20948 |

| Manufacturer | TDK InvenSense | TDK InvenSense | TDK InvenSense | TDK InvenSense | TDK InvenSense |

| Series | MotionTracking™ | - | - | - | - |

| Package/Case | 14-VFLGA | 14-VFLGA Module | 16-WFLGA Module | - | 24-TFQFN Module Exposed Pad |

| Packaging | Tape & Reel (TR) | Tape & Reel (TR) | Tape & Reel (TR) | Tape & Reel (TR) | Tape & Reel (TR) |

| Part Status | Active | Active | Not For New Designs | Active | Not For New Designs |

| Sensor Type | Accelerometer, Gyroscope, Temperature, 6 Axis | Accelerometer, Gyroscope, 6 Axis | Accelerometer, Gyroscope, Temperature, 6 Axis | Accelerometer, Gyroscope, 6 Axis | Accelerometer, Gyroscope, Magnetometer, 9 Axis |

| Output Type | I2C, SPI | I2C, I3C, SPI | I2C, SPI | - | I2C, SPI |

| Grade | - | - | - | - | - |

| Qualification | - | - | - | - | - |

| Supplier Device Package | 14-LGA (2.5x3) | 14-LGA (2.5x3) | 16-LGA (3x3) | - | 24-QFN (3x3) |

| Mounting Style | Surface Mount | Surface Mount | Surface Mount | - | Surface Mount |

| Operating Temperature | -40°C ~ 85°C | -40°C ~ 85°C | -40°C ~ 85°C | - | -40°C ~ 85°C |

inventory:10,000

Please send an inquiry. Send us your inquiry, and we will respond immediately.

-

BMI323

Bosch Sensortec

-

ICM-42670-P

TDK InvenSense

-

ICM-42605

TDK InvenSense

-

LSM6DSO32TR

STMicroelectronics

-

LSM6DSOTR

STMicroelectronics

-

LSM6DSVTR

STMicroelectronics