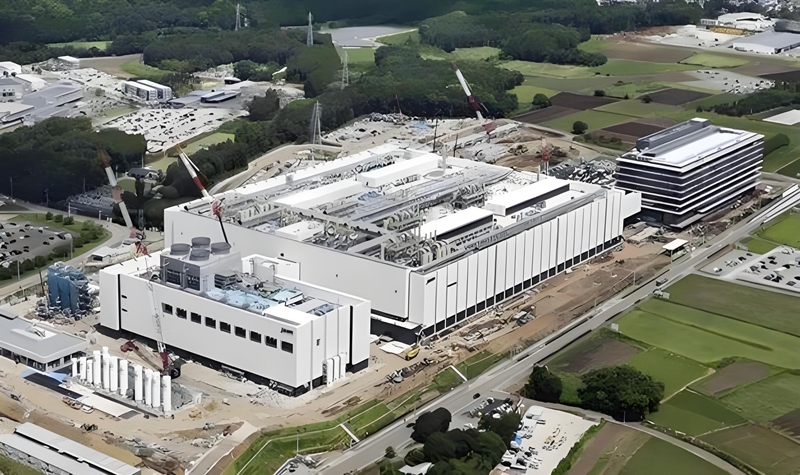

Is the construction of TSMC's second wafer fab in Kumamoto, Japan, on hold?

There is no official statement indicating the cancellation of the project. Many media outlets and industry analysts tend to believe that this is a temporary pause or a planning adjustment, closely related to the process positioning and changes in market demand.

It is reported that this suspension does not mean giving up the expansion plan in Japan. The second TSMC Kumamoto fab was originally planned to produce 6nm and 7nm chips. However, due to the rapid decline in market demand and the continuous surge in demand for AI computing power from major players like NVIDIA and Apple, TSMC is re-examining the factory design and planning, considering converting the 6nm and 7nm production lines to more advanced processes and optimizing the overall factory layout. Additionally, TSMC is also evaluating whether to introduce advanced packaging technology CoWoS to Japan.

What does it mean for the global semiconductor supply?

For the domestic supply chain in Japan

In the short term, the pace of orders related to equipment and factory construction may slow down, but the direction of semiconductor investment has not reversed. Japan still has core advantages in materials, equipment, and packaging.

For global electronic manufacturing enterprises

The overall supply of mature process wafers remains relatively stable, and there are no obvious signals of "supply disruption" or capacity contraction.

For electronic component traders

Customers need to plan in advance for alternative models of key ICs to ensure a safe inventory.

Sources have disclosed that TSMC has informed its suppliers that no new equipment will be added to the factory throughout 2026, indicating that demand for mature manufacturing processes remains sluggish. Companies need to communicate production schedules and forecasted demand in advance to reduce uncertainties and maintain transparency and flexibility in the supply chain, which are the key to coping with an uncertain environment.